Welcome to Hager, electrical distribution solutions for your residential and commercial projects

Hager products

and solutions

Check out our range of electrical installation solutions

Catalogues

We have restructured our catalogue into easy to understand offers, divided into five different application areas to give you just what you need.

-

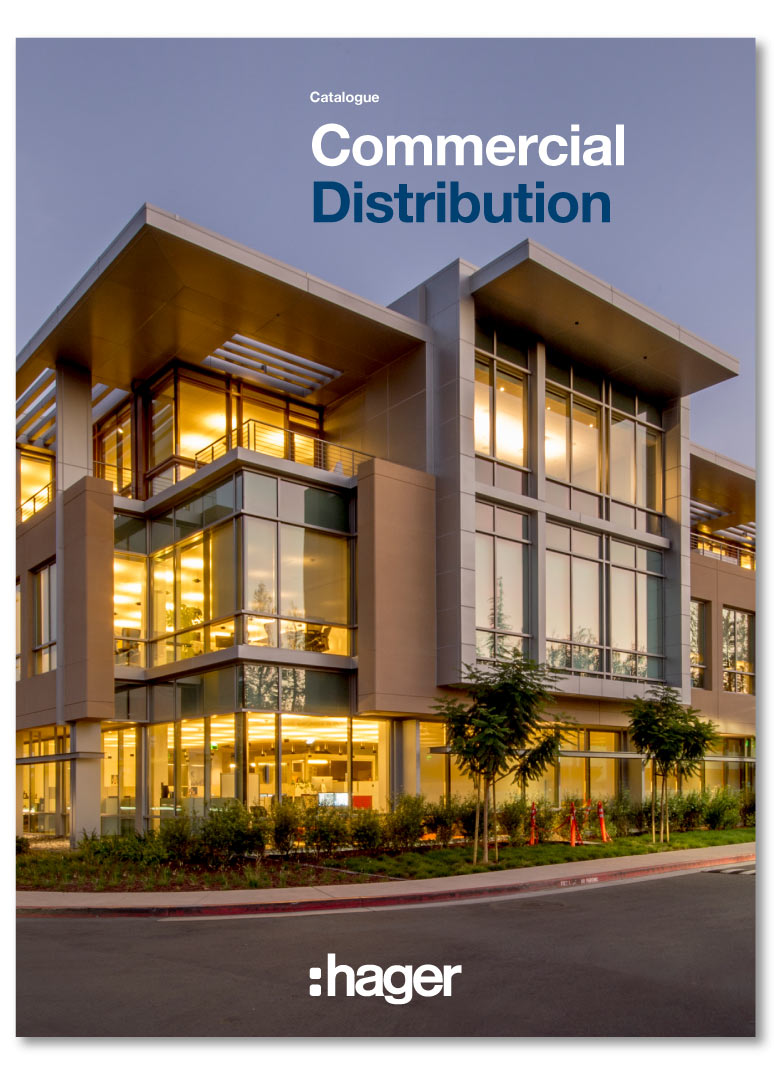

Commercial Distribution Catalogue

Solutions for commercial & industrial premises. Including our new Hybrid Invicta 3 TP&N boards, Panelboards, Plug-In Metering, protection devices and more.

pdf14.12 MB -

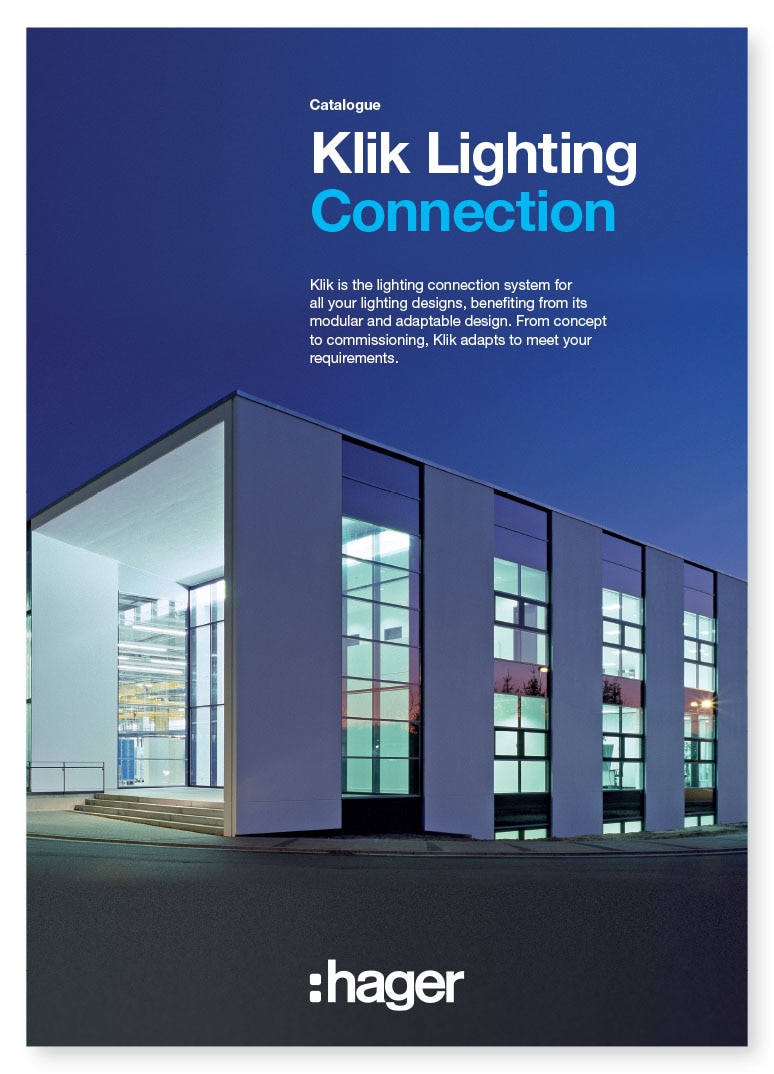

Klik Lighting Connection Catalogue

Klik is a secure lighting and control connection system that provides simultaneous mechanical and electrical connection in one plug-in action.

pdf12.14 MB -

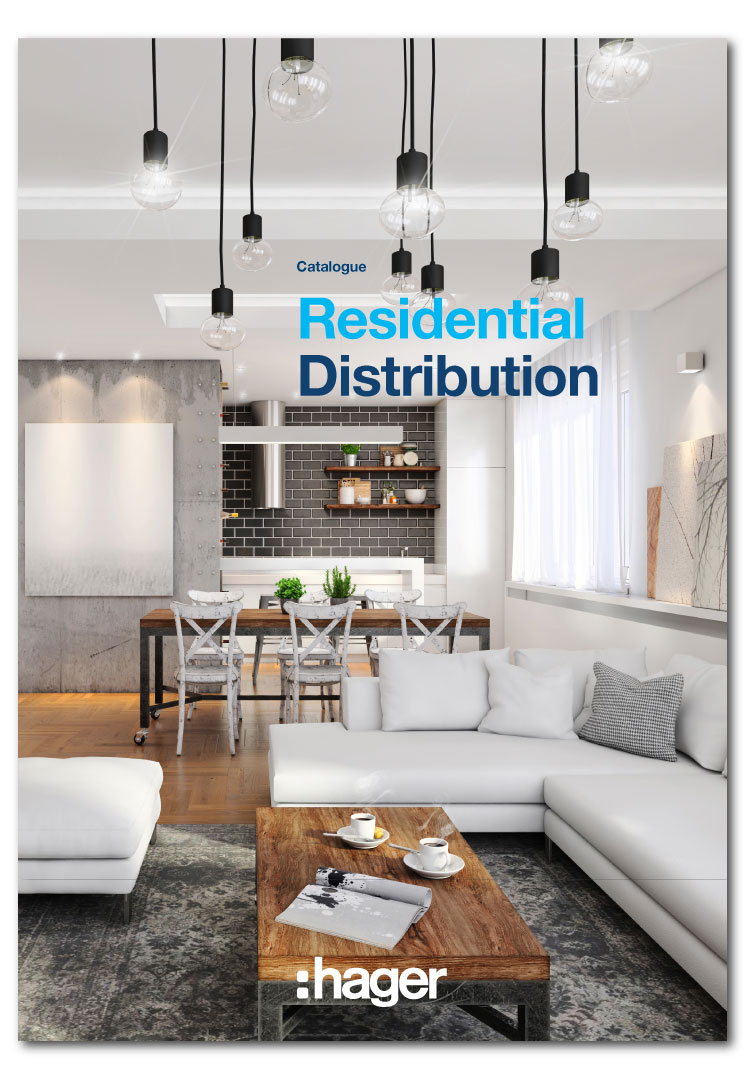

Residential Distribution Catalogue

Our new Residential Distribution Catalogue includes everything you need to know to make an informed decision on your next 18th Edition install.

pdf4.65 MB -

Included is the full range of Sollysta Wiring Accessories: White Moulded, Decorative, Grid, Metalclad and IP66. In addition we have included Junction Boxes and Ceiling Accessories.

pdf14.63 MB

"We at Hager Group will support you with the very best products, solutions and services.

And we are constantly evolving and improving."

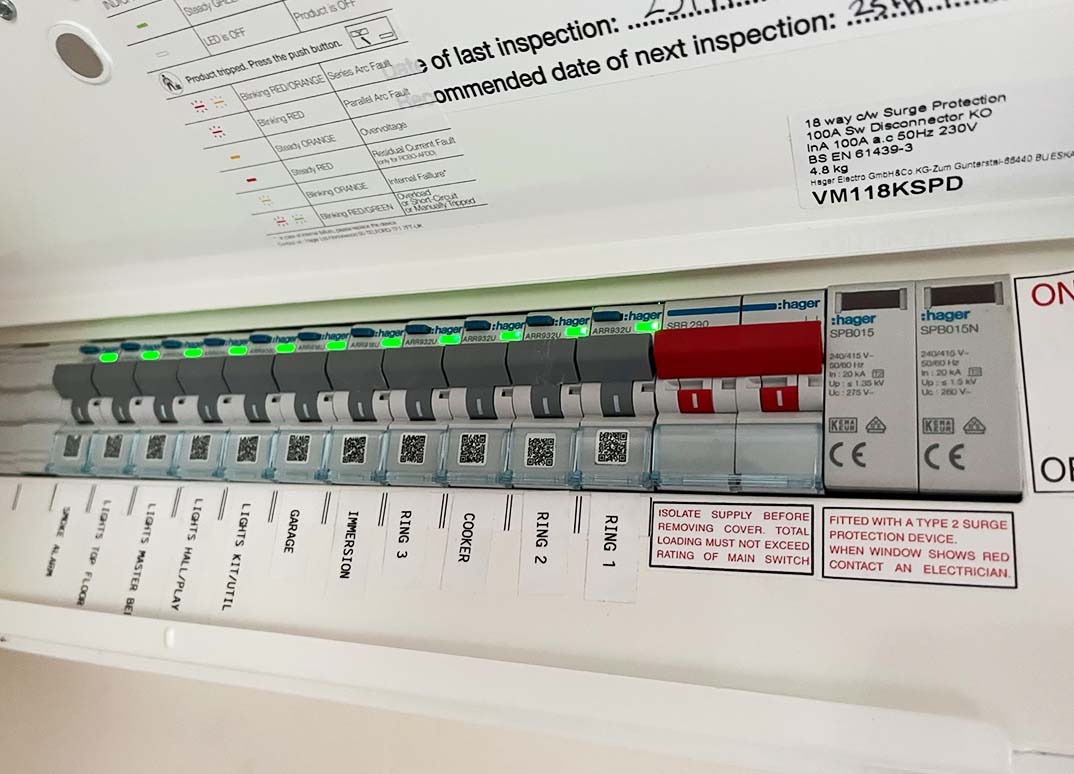

Case Study: AFDD with ProTools

Real-life feedback

Participating in the trial, Hager’s very own Country Marketing Leader, Ian Smith, had the latest single module device installed in his home.

Latest news

from Hager

Stay updated with the latest company and industry news.

Have a question?

Our team of technical experts are on hand and ready to answer any questions you may have!